|

One of the most common indicators of inter-stage valve issues is a relief valve on one of the stages discharging. This indicates that either; one of the inter-stage valves is not operating properly or the valves are worn, and the unit is likely due for a valve service at minimum. The first thing to determine is if the relief valve has gone bad or it is an issue of high inter-stage pressure. You need to determine which relief valve is leaking first and determine which stage it belongs to. Next you would have to confirm if that stage is operating at the proper pressure depending on what your final outlet pressure is. If the pressure is in its normal operating range or relatively near it, then you may be looking at a worn relief valve. If the pressure is well above its standard operating pressure, then that is an indicator that the stage after it most likely has worn valves. You would then want to approach changing the valves BUT note that all the inter-stage valves should be changed at the same time. Changing one stage while not changing the others will cause the other stages, and potentially the rings, to wear at an accelerated pace and you will have to change them shortly anyway. The only exemption to this would be if the valves are relatively new; they are either faulty valves and need to be replaced or they were not seated properly so they need to be retightened.

However, this all also depends on the unit and which stage it is. Some units could be experiencing an issue that appears to be like bad valves, but it could be caused by an issue with pressure flowing back through the ACD or Automatic Condensate Drain (if it has one). The ACD is draining the inter-stage and final oil/water separators at preset intervals and on start-up/shut down. Many ACDs are set up to rely on control pressure from one stage maintain another. In those cases, an issue with the ACD may cause higher stage pressure to flow back through the ACD into a lower stage. If your unit has a substantial amount of hours, say above 1000-2000, or has not been serviced for years (5 or more depending on use and location), it may simply be due for a valve job and it is usually a good idea to service the ACD at the same time. If you're looking for valves you can check out our selection of Bauer Compressor Valves here.

7 Comments

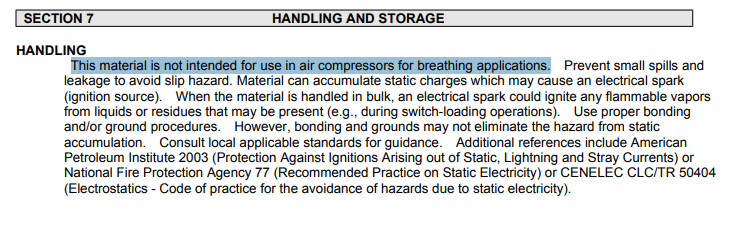

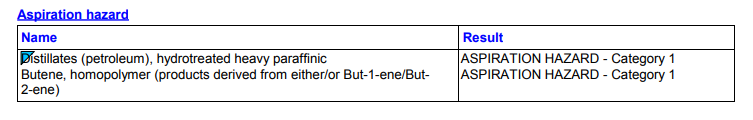

Avid SCUBA enthusiasts dream of owning their own compressor for SCUBA fills. No more lugging tanks to the shop or waiting for fills. Personal compressors for home use can generally run from $3,000 - $15,000.00 depending if you buy new or used, big or small, simple or upgraded. My Dad always told me “if it seems to good to be true – it is!” I’m talking $500.00 compressors from Amazon and Walmart Marketplace that can fill SCUBA tanks, car tires, air rifles, and perhaps my Macy’s Day Parade balloon… You’ll see them under the names Yong Heng, Orion and Davy – all similar styles. These compressors will reach a high enough PSI to fill a scuba tank, but there are extra steps you need to take to ensure you’re putting safe, breathable air in your tank. You could be poisoning yourself with Carbon Monoxide, Hydrocarbons and various other elements found in the ambient air compressed or the oil used in the compressor. Proper filtration needs to be added on to these style compressors. Those little wads that they come with are not doing enough filtration/purification alone if you are using these for breathing air. As for oil – I’m going to say this as loud as I can so the people in the back of the room can hear… MOBIL RARUS IS NOT FOR BREATHING AIR USE It says so right in the SDS sheet: I know.. I know.. Royal Purple though… Why do you want to use something that says it’s an “Aspiration Hazard” in a compressor that pumps air you’re going to be breathing. Compressed air 101 – oil can and will get into the air stream. An oil and water separation is often not the stand alone solution to remove all of the oil from the air you’re putting into your tank. Please choose an oil that is designed for breathing air applications. C.A.S.E. Has 3 different breathing air safe options for these compressors. Blended to an ISO grade 46 – we even have a food grade option available. Why take a chance? Our premium lubricants will do wonders for your compressor. Have one of these and need some assistance? We specialize in breathing air systems and would be happy to help improve your set up with filtration, oil or anything else you may need. C.A.S.E. Recommends the ISO Grade 46 (20 weight) CF-1046, CF-2046 or the CF-8046 for your Yong Heng compressor when using it for breathing air and filling dive tanks. We have these ready to ship in quarts & gallons. Order today!

C.A.S.E. will be out in force at DEMA 2019 to help answer your compressor questions! Need parts? We got you – get your orders in now and we will gladly bring them to you at the show. C.A.S.E. will be in Bauer booth 1531 and walking the floor, come say hello!

As most of our staff will be in attendance our office will be running with limited staff from November 13th – the 16th. We are still here to answer your emails and fill your orders. We will be scheduling appointments now for before and after DEMA so get your name on the list before it’s too late. See you in Orlando! . . . Pssstttt if you’re still reading this and dig cool Tiki themed dive bars - Megz is low key trying to take over Trader Sam’s Grog Grotto at Disney’s Polynesian Resort one night during the week. It only holds about 50 people and she’s positive we can turn this into the unofficial DEMA Dive Party. Let us know if you’re interested. It was a busy summer over here at C.A.S.E. – We’ve been all over the place making sure our customers are up and able to fill to their heart’s content. Our staff works hard so your equipment can work harder. If you’re just finding our site – welcome! Give us a call or send a message anytime. We’re here to answer your high pressure breathing air problems.

From custom blended lubricants to air testing – we do it all. Our experts have over 50 years of experience with top breathing air compressor brands such as Bauer Compressors, Inc., Coltri, Nuvair, Nardi, L&W, and more. Fire departments, yachts, cruise ships and in shop repairs to name a few of the places we’ll go for our clients. We travel near, far, or wherever you are to get the job done. Come have a laugh and learn a thing or two! We’re on Facebook, Instagram, WhatsApp, Twitter, Call – Email – or Text us!

Heat and humidity can take a huge toll on the life of your oil. In tropical conditions your oil will breakdown before some factory recommendations. Understanding the compressor size, oil system and operating conditions will allow you to choose an oil change interval that works best for your compressor. We generally recommend the below for high pressure air systems used in breathing air applications:

Portable compressors like the Bauer JRII or Bauer Oceanus we suggest every 50 hours Standard compressors 13 to 26 CFM units like the Bauer Vertecon 13 we suggest every 150 to 200 hours Large compressors 30 + CFM units like the Bauer K42 or Bauer K60 we suggest every 300 to 350 hours Always contact your service center with your system information and they will help ensure you are using not only the right lubrication, but changing it at the correct intervals. We're adding even more parts and compressors to the site daily! Want to see something added to the website? Reach out to [email protected] with your requests. shop our store

CLICKMATE C1-144146

$690.00

CLICKMATE Quick connector CGA347/CGA346 with integrated Bleeding valve and small lever operator left side

Bauer JRII-E1

$6,461.00

Bauer JRII-E1 portable breathing air compressor

STANDARD SCOPE OF SUPPLY › BAUER P0 breathing air purification system › Belt guard designed to meet OSHA guidelines › Inlet filter › Vibration isolators › High temperature switch (G drives) › Five foot fill hose assembly with SCUBA yoke, bleed valve and pressure gauge SYSTEM FOOTPRINT › JRII-E1/E3: 27” x 14” x 17” (686mm x 356mm x 432mm) AVAILABLE ACCESSORIES (FACTORY INSTALLED) › Visual CO/Moisture monitor indicator › Final pressure switch for gasoline engine › Hourmeter/Tachometer (G drive)

CF-8000

$31.56 - $5,245.76

Tri Ester Blended Lubricant with exceptional anti-wear properties , unsurpassed resistance to carbon build up and superior self-cooling and heat transfer properties. This is the best fluid for compressors in high temperature , hot running areas and extreme conditions.

You can’t afford to wait for new equipment. Now you don’t have to. With Marlin, you can get the new equipment you need today and pay for it over time.

We know you're ready for Mini Season, but is your compressor ready? Any new noises, smells or vibrations you've noticed, but are just hoping go away? You've got tanks to fill and money to make, why risk your compressor going down. Have one of our professional compressor technicians come and take a look. We'll keep you up and running ( and making money!)

Want to fix your own compressor? No problem! We have the parts and training to get the job done! The next CASE Compressor Course is August 14-16th. Sign up today and come and learn from the best in the business! |

CASEFrom Sales to Service we do it all! Check back here for more updates about what's going on at Compressed Air Supplies. Archives

August 2020

|

COMPANY |

QUALITY PRODUCTS & SERVICESWE ARE A FAMILY OWNED BUSINESS THAT STRIVES FOR NOTHING BUT THE BEST IN SERVICES, SALES, INSTALLATION, AND OVERALL CUSTOMER SERVICE!

|

CONTACT USINTERESTED IN OUR PRODUCTS OR SERVICES?

CALL US TODAY TO SPEAK TO OUR KNOWLEDGEABLE STAFF 954-929-4462 |

Privacy Policy, FAQs & Return Policy

Call: 954-929-4462 |

Fax: 954-929-4463 |

SMS & WhatsApp: 954-780-6630 |

COMPRESSED AIR SUPPLIES & EQUIPMENT INC © ALL RIGHTS RESERVED 2004-2024

RSS Feed

RSS Feed